Our Sofa Construction

Our sofas are built to offer lasting comfort for 5 years and more.

This is supported by partnership with quality focused factories and selective use of durable materials.

Sofa Construction Process

-

1 - Construcing the Frame

Kiln dried solid larch wood is cut based on sofa dimensional. Screws and staples are used to connect the wooden pieces to form the frame. Corner blocks are added to enhance stability.

-

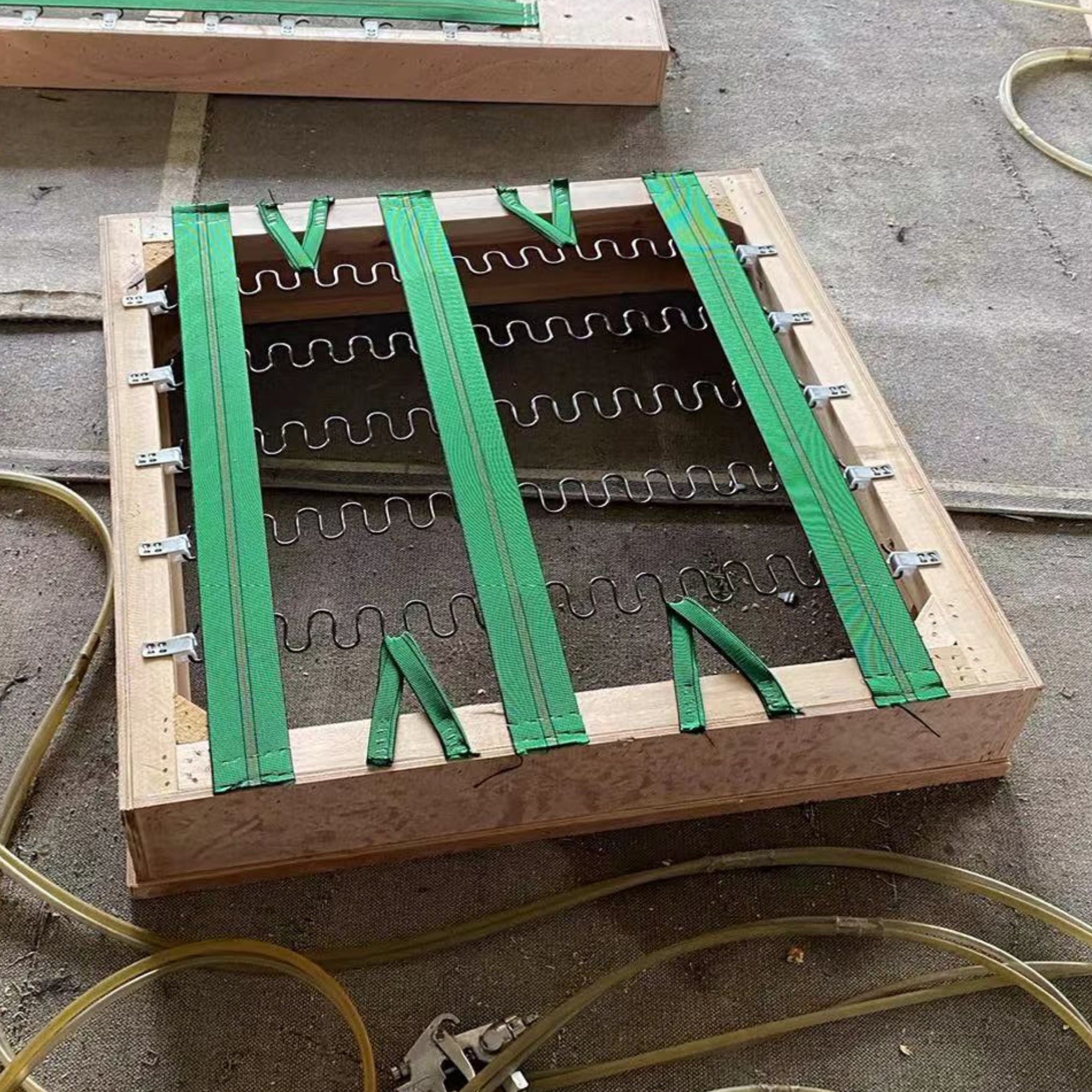

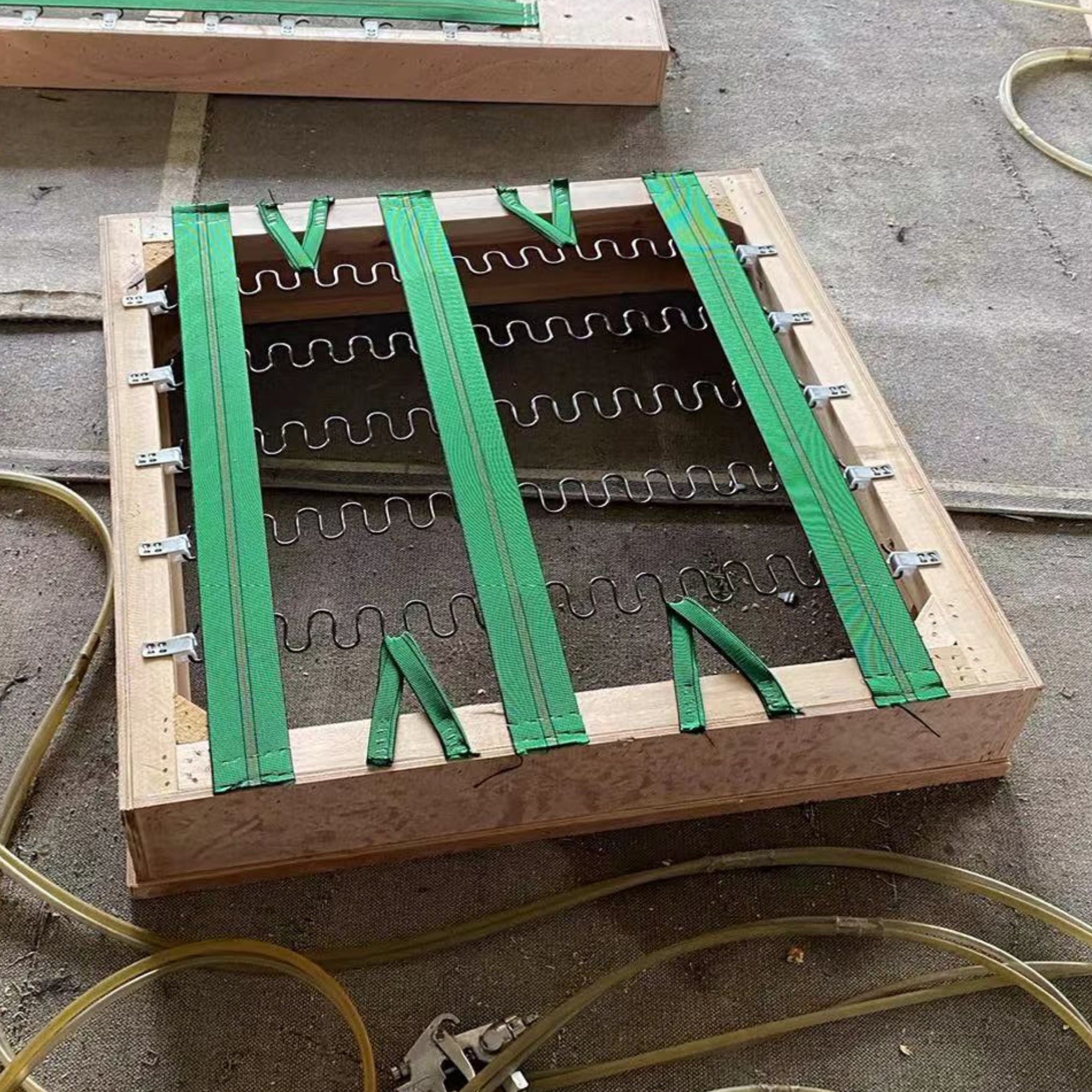

2 - Installing Suspensions

5mm thick carbon steel zigzag springs are installed to offer seat comfort. For a 2.0m 3 seater sofa, about 8 - 10 zigzag springs are used to act as support and evenly distribute weight on the sofa.

-

3 - Making Cushions

High density foams, polyester fibres and down feather are used to create the seat and back cushions. High density foams at least 11cm thick are used for seat cushions.

-

4 - Preparing the Upholstery

Fabric or leather are cut and sewn together to form the sofa upholstery. The materials we chose are tested for durability by key testing agencies such as SGS, Intertek and CTi.

-

5 - Assembling and Cleaning

Different sofa components made separately are assembled together to create the final product. Post assembly, it undergoes airjet cleaning process to remove dusts before packing.

-

6 - Inspection and Packing

The completed sofa is inspected for dimensions, stitching, and upholstery mounting quality. They are then packed with at least three protective layers to prevent damage during shipping.

Our Past Sofa Constructions

Explore Our Sofas-

Calm Full Leather Sofa

Width: 180cm

Colour: White

Other customizations: N/A

-

Chalet Half Leather Sofa

Width: 180cm

Colour: Brown

Other customizations: N/A

-

Charles Faux Leather Sofa

Width: 180cm

Colour: Green

Other customizations: N/A

-

Cedar Fabric Sofa

Width: 180cm

Colour: Grey (Customized)

Other customizations: Armless unit

-

Cubix Fabric One Arm Sofa

Width: 200cm

Colour: Beige (Customized, easy clean fabric)

Other customizations: N/A -

Crystal Fabric Sofa

Width: 200cm

Colour: Beige (Customized, pet friendly fabric)

Other customizations: N/A

-

Cubix Fabric Sofa

Width: 200cm

Colour: Brown

Other customizations: N/A

-

Cuddle Half Leather Sofa

Width: 200cm

Colour: Light grey (Customized)

Other customizations: N/A

-

Charmy Fabric Sofa

Width: 205cm (Customized)

Colour: White

Other customizations: Stain and water resistance

-

Colby Half Leather Sofa

Width: 210cm

Colour: White

Other customizations: Closed piping stitchings

-

Cove Fabric Sofa

Width: 210cm

Colour: Grey (Customized)

Other customizations: N/A

-

Cashew Fabric Sofa

Width: 215cm

Colour: White

Other customizations: N/A

-

Casper Fabric Sofa

Width: 220cm

Colour: White (Customized)

Other customizations: N/A

-

Coastal Fabric Sofa

Width: 220cm

Fabric: Grey

Other customizations: N/A

-

Castle Faux Leather Sofa

Width: 220cm

Colour: Brown

Other customizations: N/A

-

Cloud Fabric Sofa

Width: 228cm

Colour: White

Other customizations: N/A

-

Claudia Fabric Sofa

Width: 240cm

Colour: White

Other customizations: Stain and water resistance

-

Clora Half Leather Sofa

Width: 240cm

Colour: Beige

Other customizations: N/A

-

Castle Faux Leather L Shape Sectional Sofa

Width: 240cm

Colour: Dark brown

Other customizations: N/A

-

Cubix Fabric Adjustable Backrest Sofa

Width: 240cm

Colour: Green (Customized, pet friendly fabric)

Other customizations: N/A

-

Crystal Fabric One Arm Sofa

Width: 240cm

Colour: Blue (Customized, suede fabric)

Other customizations: N/A

-

Carson Full Leather Sofa

Width: 240cm

Colour: Black (Customized)

Other customizations: N/A

-

Comfy Half Leather Sofa

Width: 260cm

Colour: Brown

Other customizations: N/A

-

Crescent Fabric L Shape Sectional Sofa

Width: 280cm

Colour: Light grey (Customized)

Other customizations: N/A

-

Cynthia Fabric One Arm Sofa

Width: 280cm

Colour: Grey (Customized)

Other customizations: N/A

-

Claudia Fabric L Shape One Arm Sectional Sofa

Width: 300cm

Colour: White

Other customizations: N/A

-

Crystal Fabric L Shape Sectional Sofa

Width: 310cm (Customized)

Colour: Grey (Customized, pet friendly fabric)

Other customizations: N/A

-

Cubix Fabric L Shape Sectional One Arm Sofa

Width: 300cm (Customized)

Fabric: Grey (Customized)

Other customizations: U shape configuration