Sofa Material Selection

Fabric

We use polyester blends with cotton, linen and acrylic in our sofas.

These blends have the advantages of both man-made and natural fibers:

- Polyester: durable, easy to clean and wrinkle resistant

- Cotton: soft and breathable providing high comfort

- Linen: have a natural luster and smooth to touch

- Acrylic: resistance to sunlight, low moisture absorbency and fast drying

In addition, we only choose fabrics that record > 15,000 rubs under the Martindale test to ensure that our sofa can last for > 5 years of normal daily use.

This rub count is a key indicator of fabric durability as shown in the table.

| Rub count | Average lifespan | Use case |

|---|---|---|

| < 10,000 | < 3 years | Suitable for decorative purposes |

| 10,000 - 15,000 | 3 - 5 years | Suitable for occasional use |

| 15,000 - 25,000 | 5 - 8 years | Suitable for everyday use |

| > 25,000 | > 8 years | Suitable for heavy duty use |

Leather

We use top grain cow leather with a pigmented finish that is comfortable, durable and easy to maintain:

- Top grain leather: soft, smooth and cooling to touch, has great durability and strength

- Light pigment finish: stain and water resist, making our sofas easier to maintain

We do not use split leather, bonded leather or faux leather for contact areas of the sofa. These materials are likely to break down in < 5 years with regular use and provide less comfort.

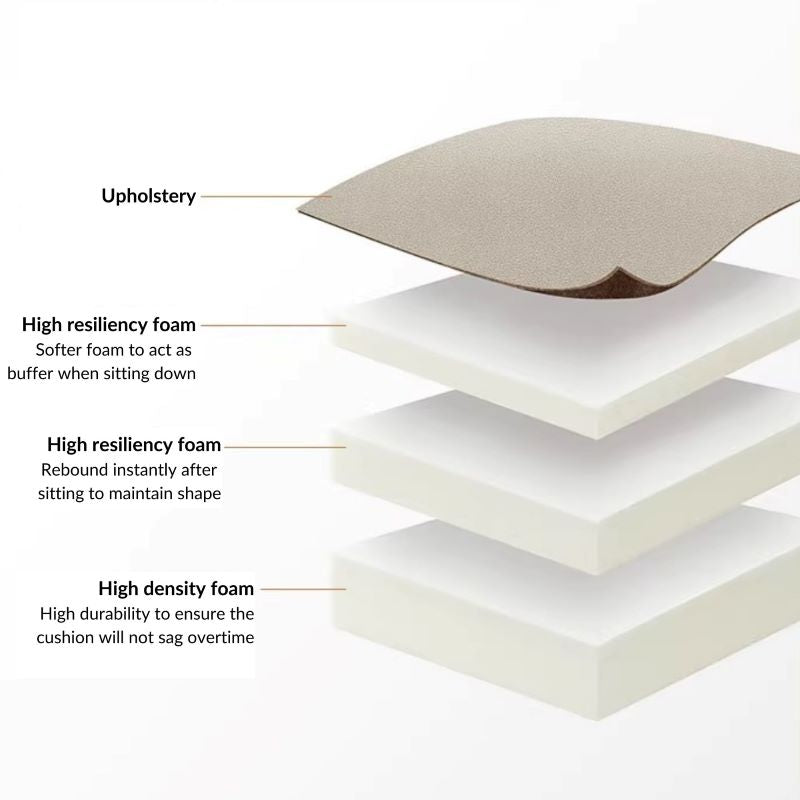

Cushion

We use high-density foams that weigh >= 45kg/cbm (density) in our seat and backrest cushions. Additionally, we ensure that the total combined foam thickness in our seat cushions is >= 11 cm. This prevents customers from feeling the frame while seated and enhances durability by helping the cushions maintain their shape over time.

The high density and thickness choice for seat cushions ensure that they can withstand 100,000 pressure tests without noticeable deformation.

The common relationship between foam density, thickness and cushion lifespan is as shown in the table.

|

Density (kg/cbm) |

Thickness (cm) |

Average lifespan (years) |

|---|---|---|

| 28 | 8 | 2 - 3 years |

| 28 | 11 | 3 - 5 years |

| 32 | 11 | 5 - 10 years |

| 38 - 45 | 11 | > 10 years |

Foams used in our cushions also offer the following benefits:

- Safe for everyday use with no volatile organic compound emissions

- Antimicrobial

- Environmentally friendly

We do not use pocket coils as they are prone to poke through and sag over time under normal wear and tear.

Frame

We use kiln-dried solid larch wood in our sofa frames.

It is one of the strongest coniferous species in the world with the following characteristics:

- Density >= 650kg/cbm

- Air-dry density within 0.51g/ccm - 0.69g/ccm

Before use, it is treated to be more durable and resistant against mold and cracking in the following ways:

- Kiln drying at 70°C - 80°C for 7 consecutive days to bring moisture content within 10% - 14%

- Anti-insect, antifungal and anti-termite treatment

Combined, this ensures that our frames can last for > 10 years without any form of deformation.

Suspension

We use 5mm thick carbon steel zigzag springs for our sofa suspension. Each pair of zigzag springs can support a weight of up to 75 kg.

This ensures optimal support throughout the entire sofa for the user for > 5 years.

To further enhance the stability of our sofas, we also add webbing, twine and silent clips to extend the lifespan of zigzag spring.

- Webbing: Made of polyester and nylon to provide elasticity and support

- Twine: Made of durable ropes to ensure the stability of the spring system

- Silent clips: Made of steel and resins to reduce noise and vibration from the springs

Last update: 14th Feb 2025